Predictive Maintenance

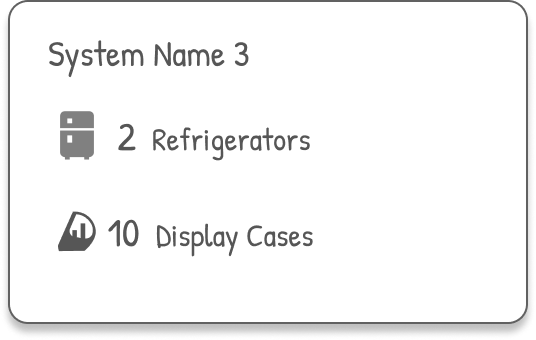

Arimo’s Predictive Maintenance is a Deep-Learning powered AI solution which notifies maintenance engineers at OEM (Original Equipment Manufacturers) to detect any equipment problem for things like Refrigerators, Display Cases, Air Conditioners, at customer location ahead of time.

The value this brings for Panasonic is saving the budget by not having to replace problem equipment entirely. On the tactile level, this also helps reduce making several trips to diagnose the issue and a separate trip to repair the malfunctioned part. This also reduces customer equipment downtime, which in turn improves customer experience.

My Role

Principal UX

Company

Arimo - Panasonic Company

Background

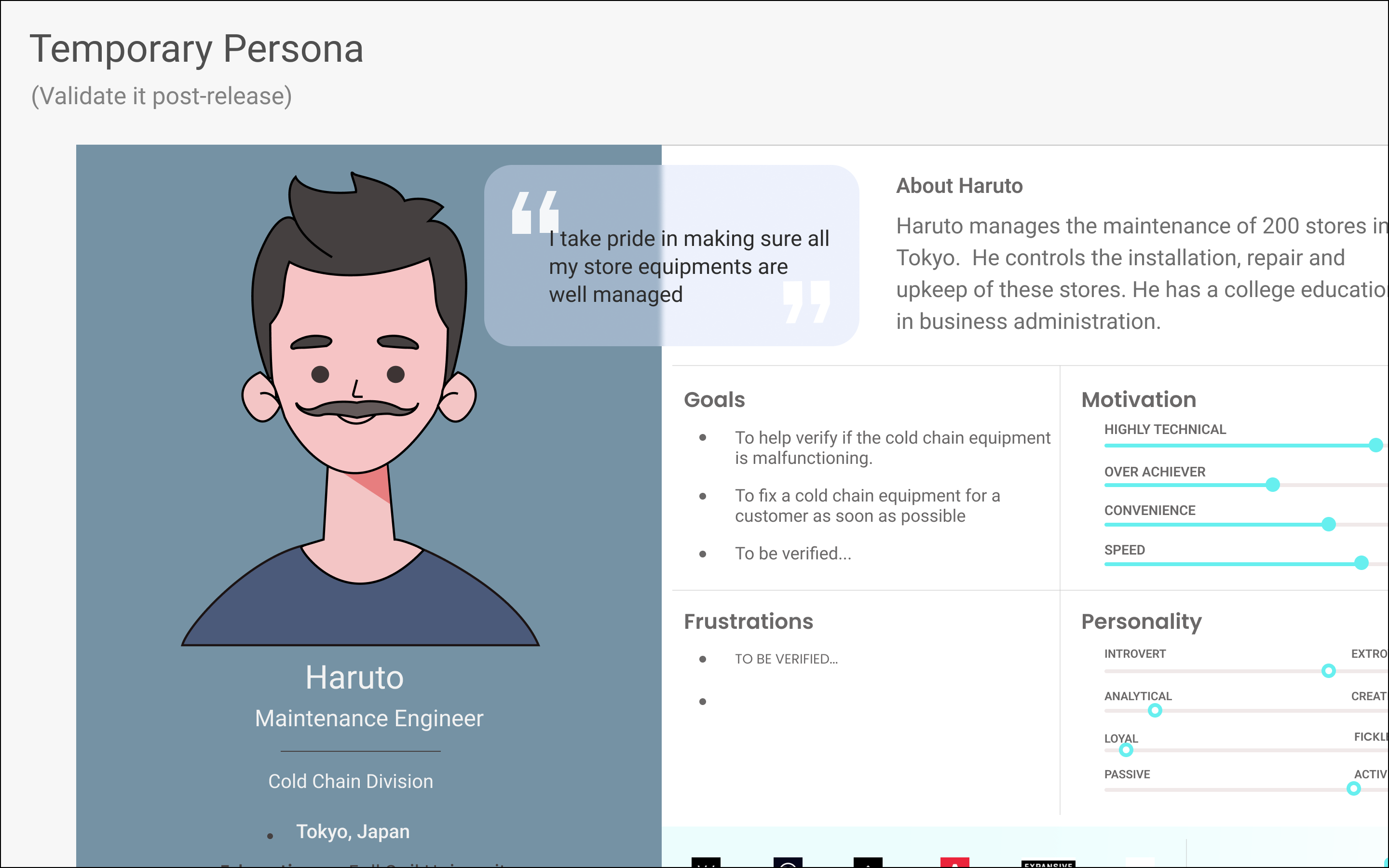

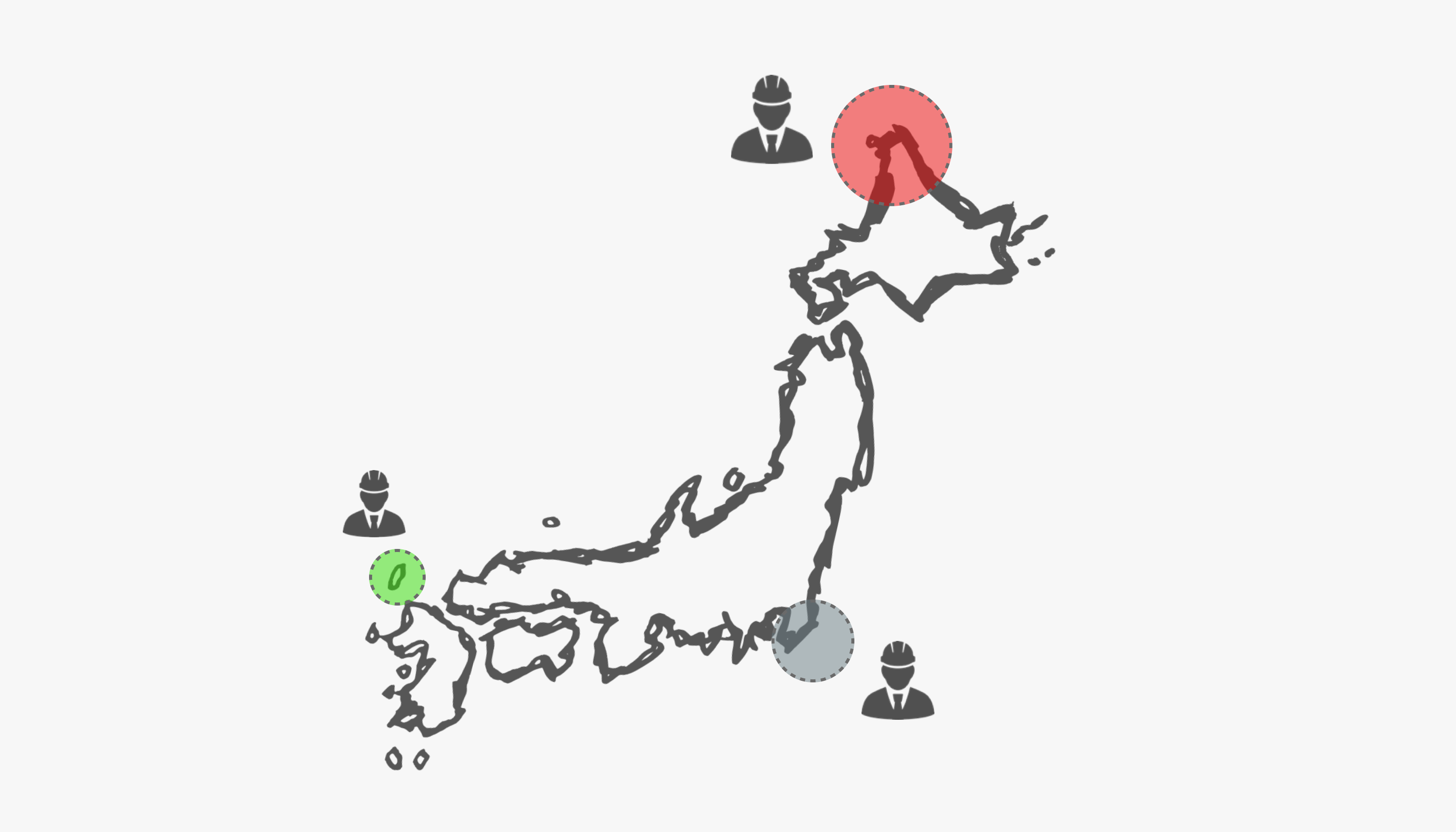

Region Specific - Maintenance Engineers

Managing stores within their region

Setting The Stage

Panasonic & Customer Goals

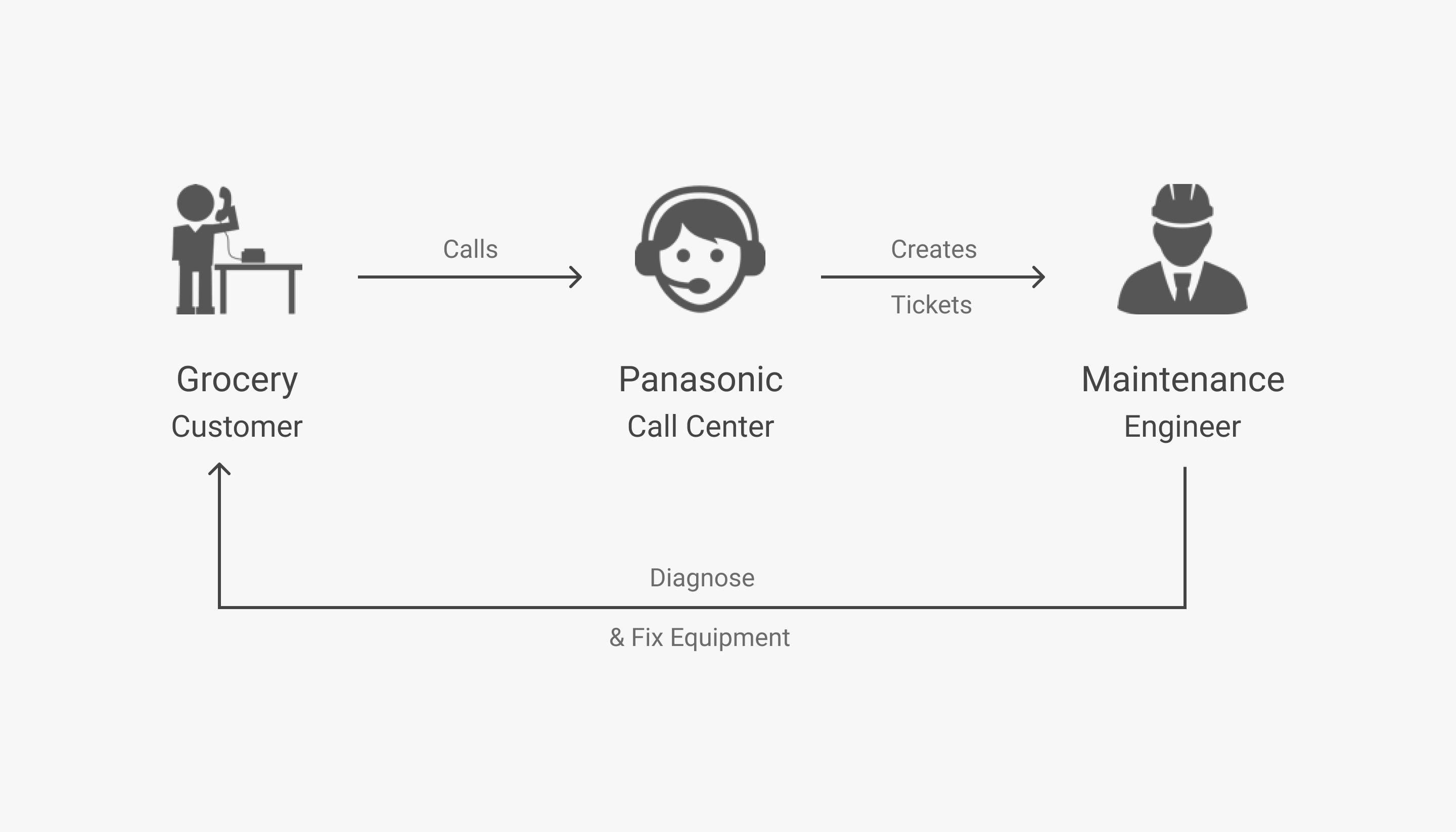

Existing Diagnosis Process

Collaborated With Product Owner

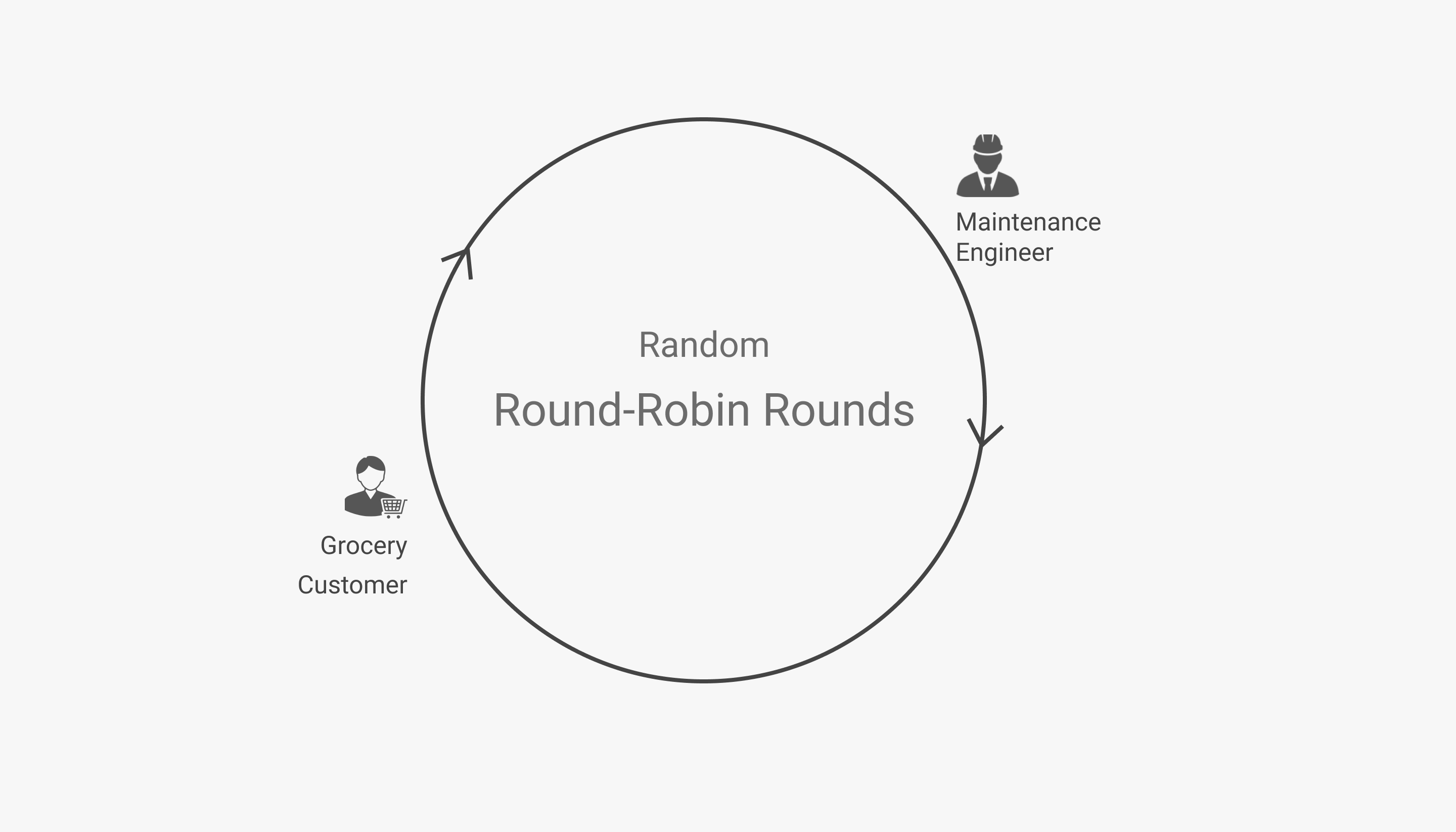

Random Round Robins

The Maintenance Engineer adheres to a daily routine, overseeing equipment that does not require servicing.

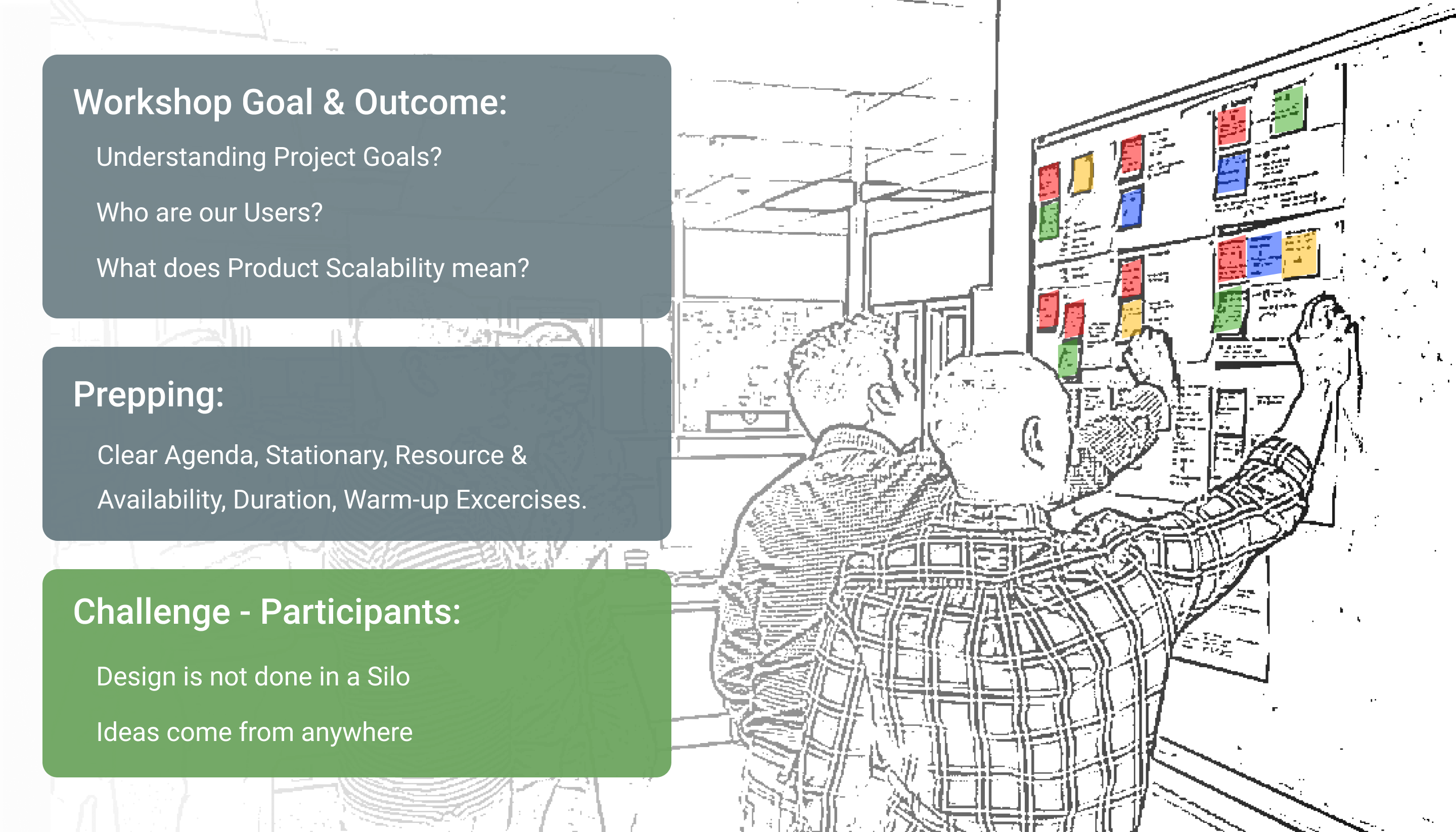

Pre-Design Workshop

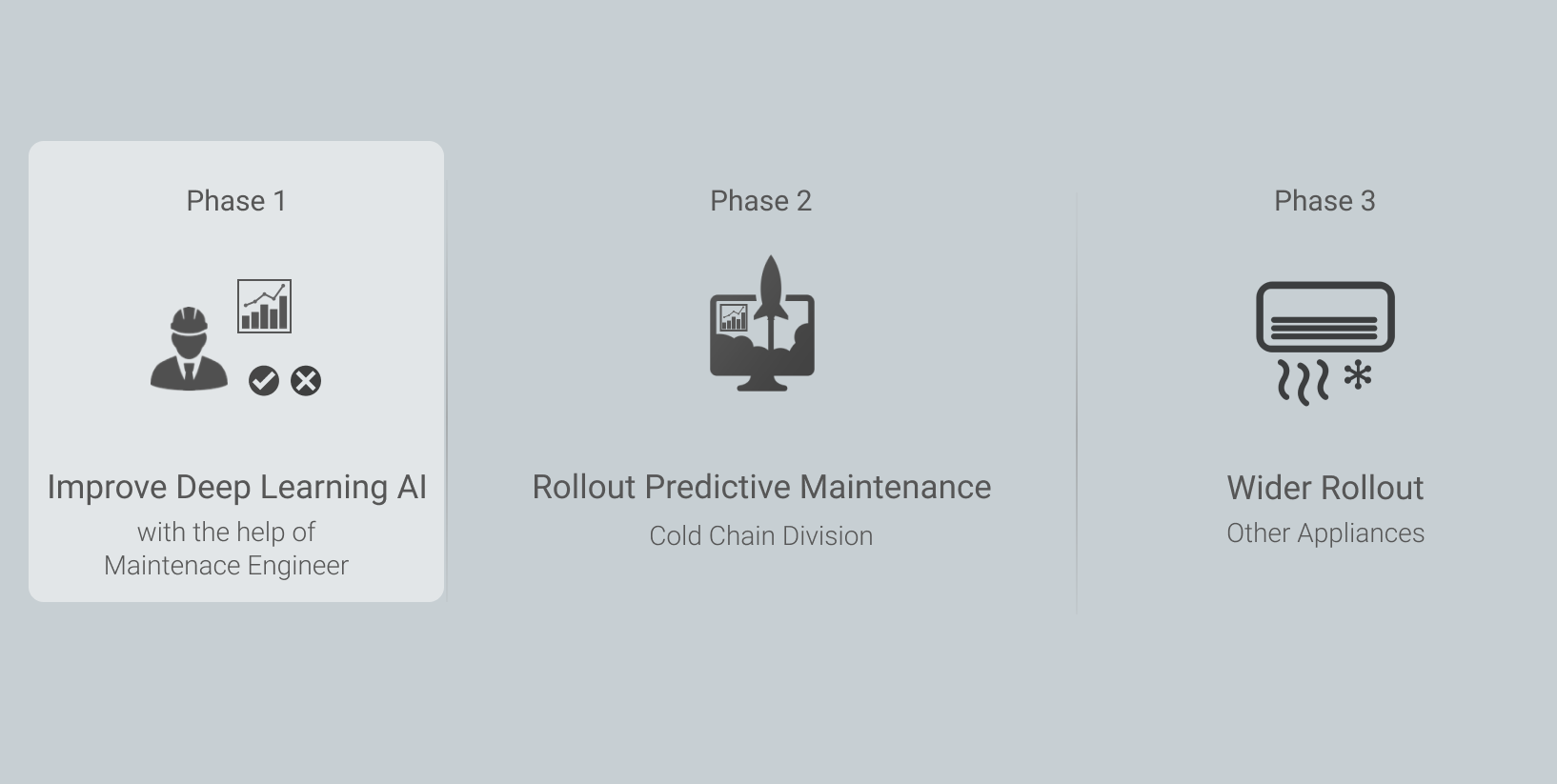

Product Roadmap

User Goal

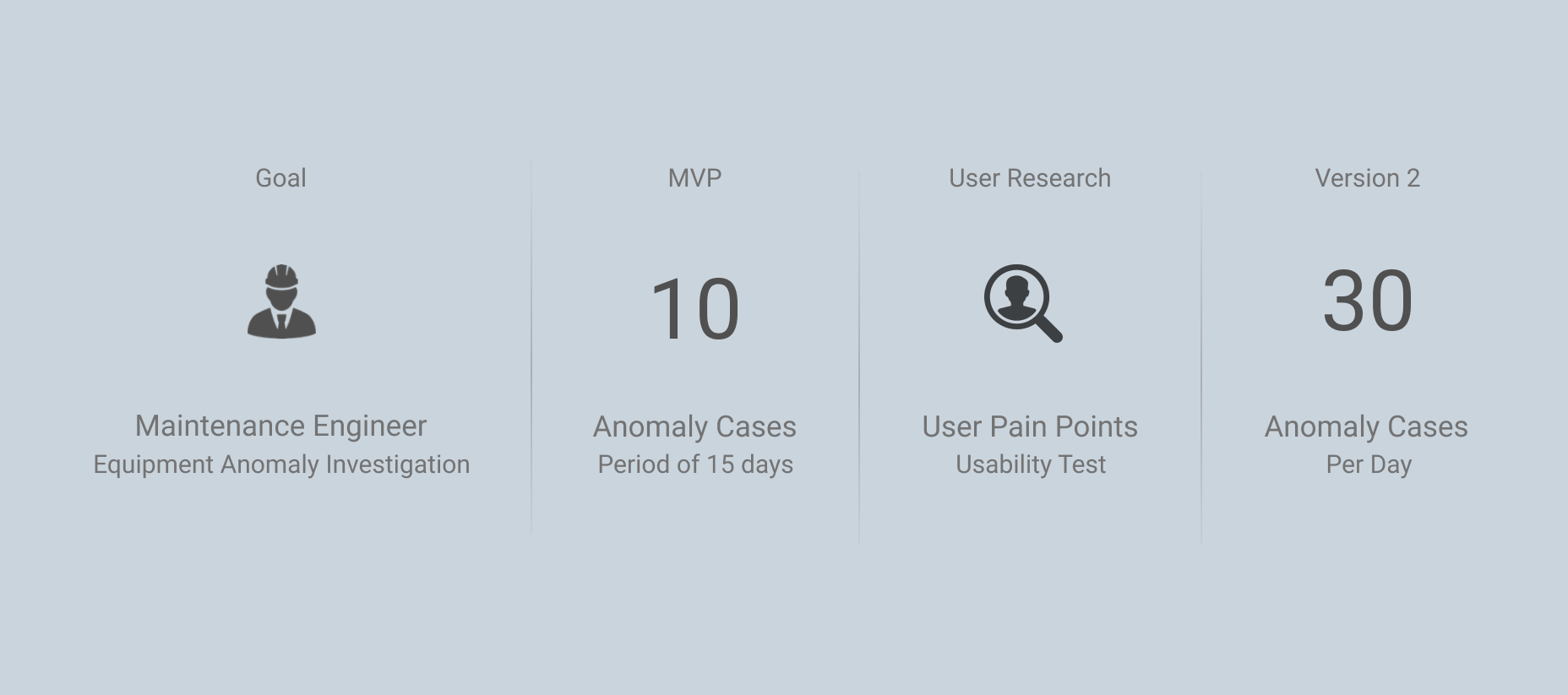

Help Maintenance Engineers Diagnose Anomalous Equipment Cases Successfully

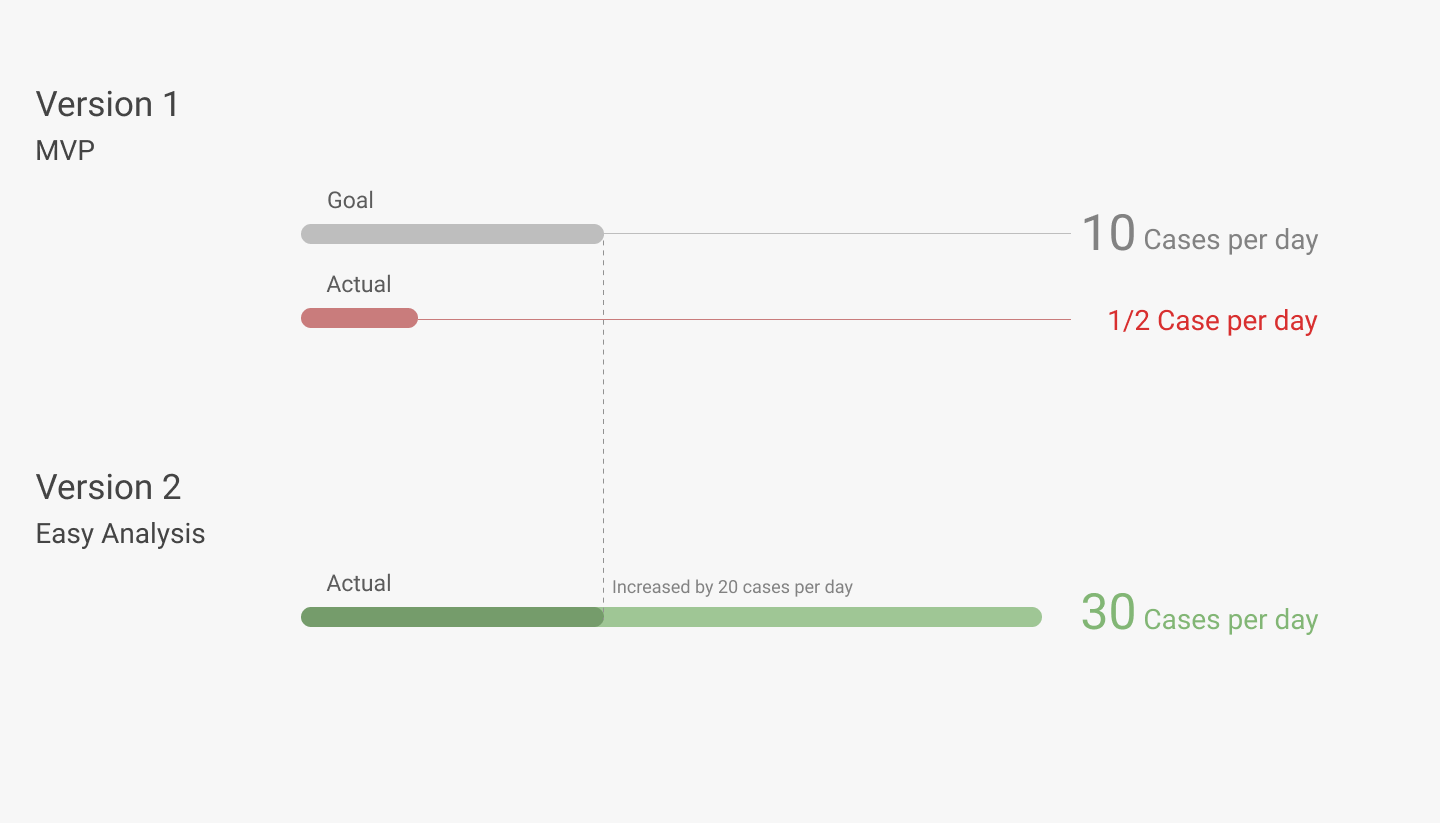

Success Criteria

Diagnosing 10 Anomaly Cases Per Day

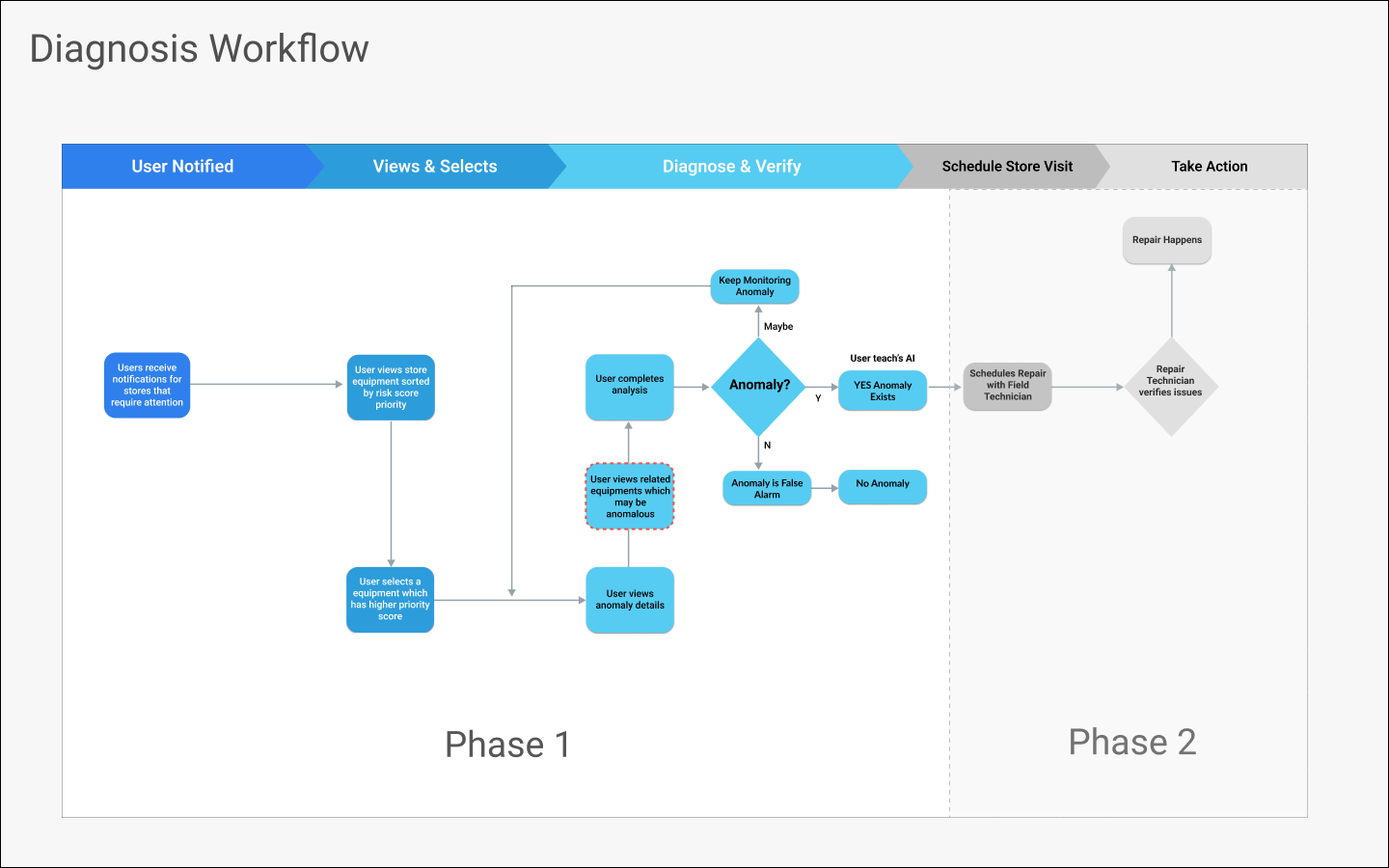

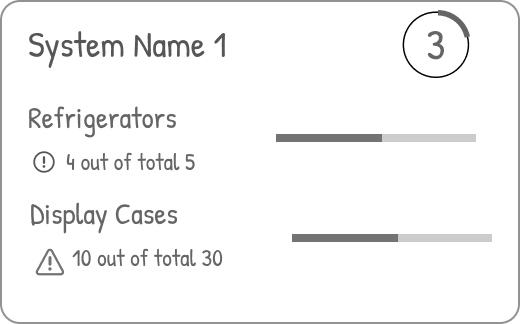

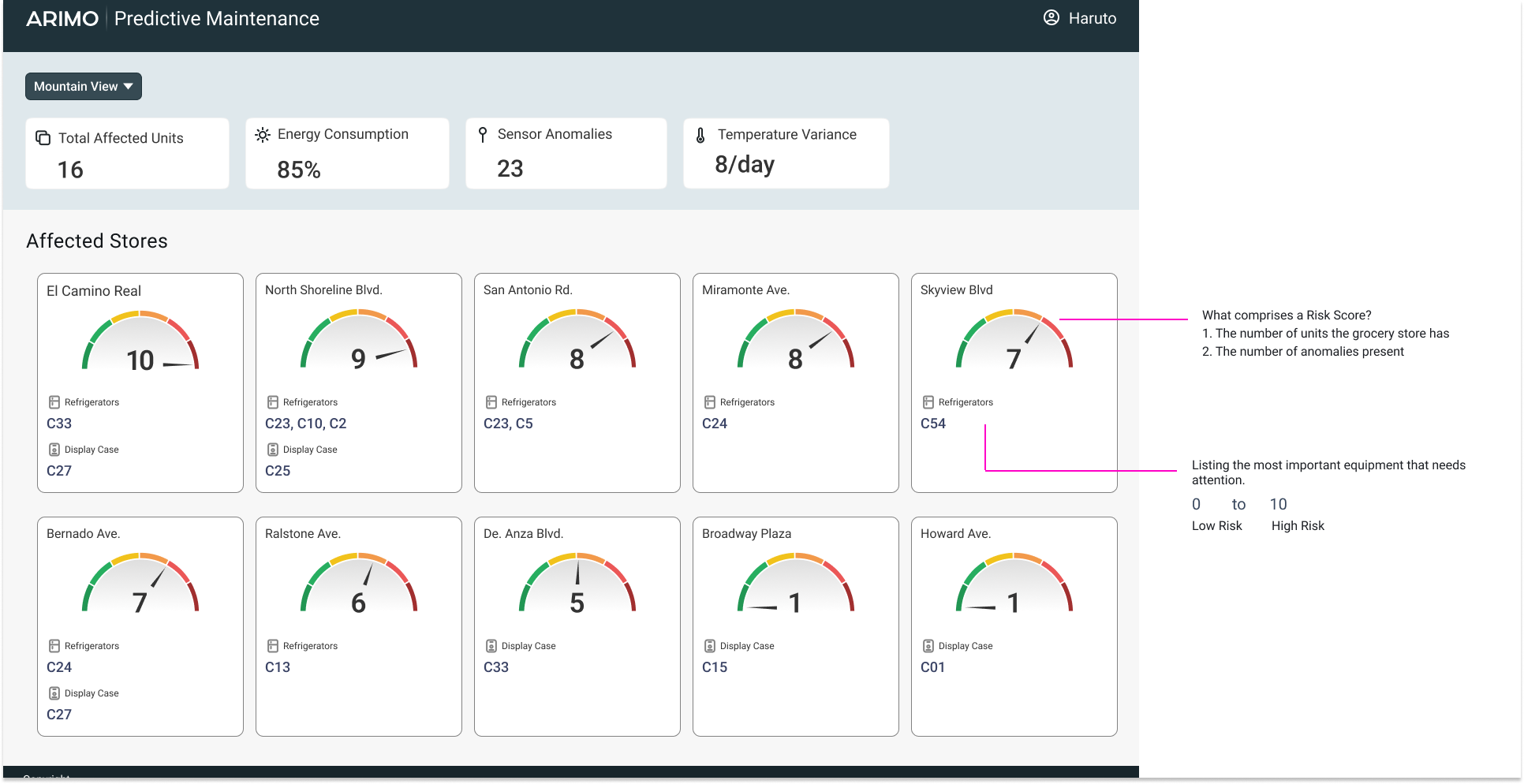

Landing Page

How might we help the maintenance engineer identify the most anomalous equipment?

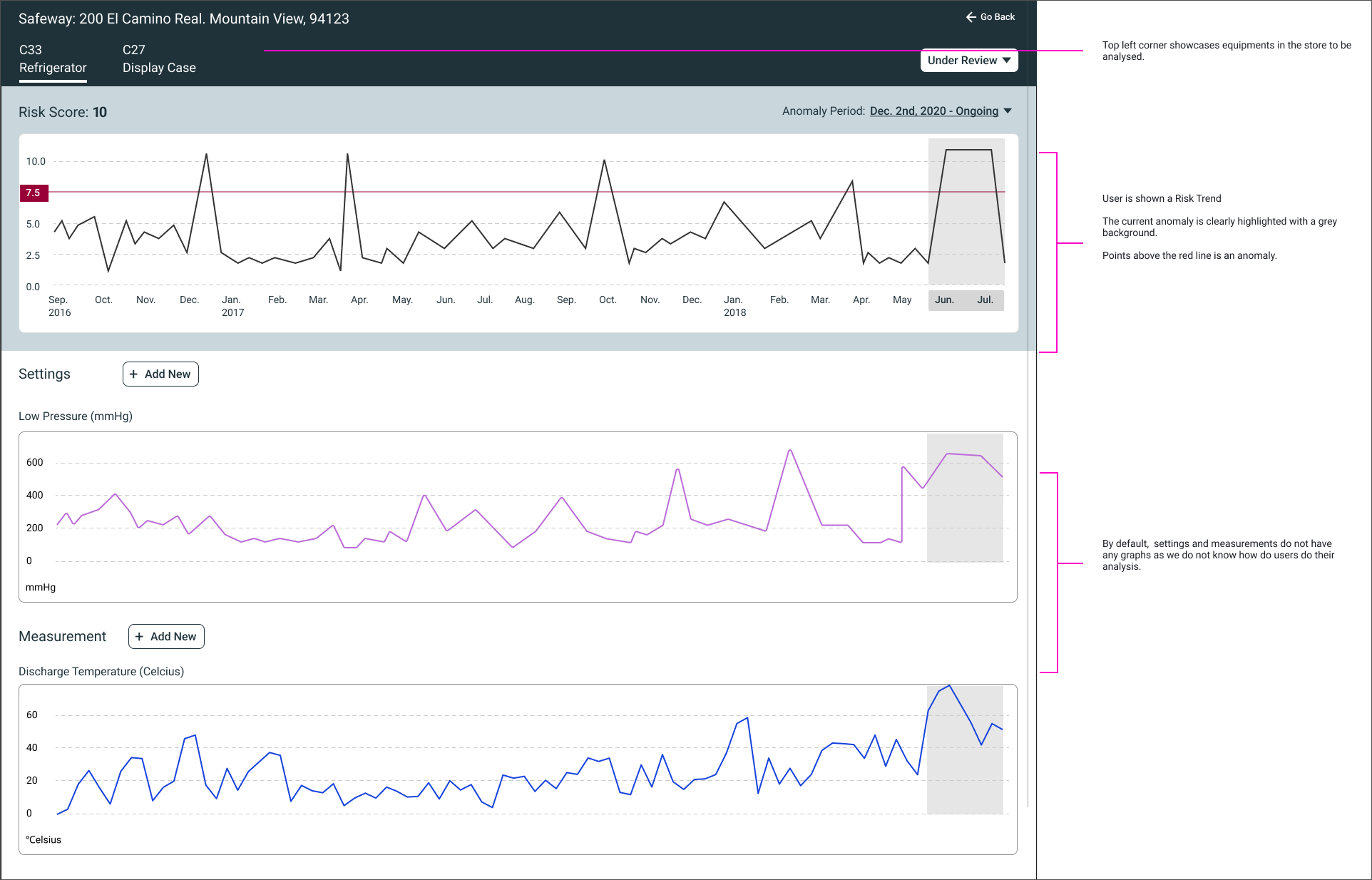

Detail Page

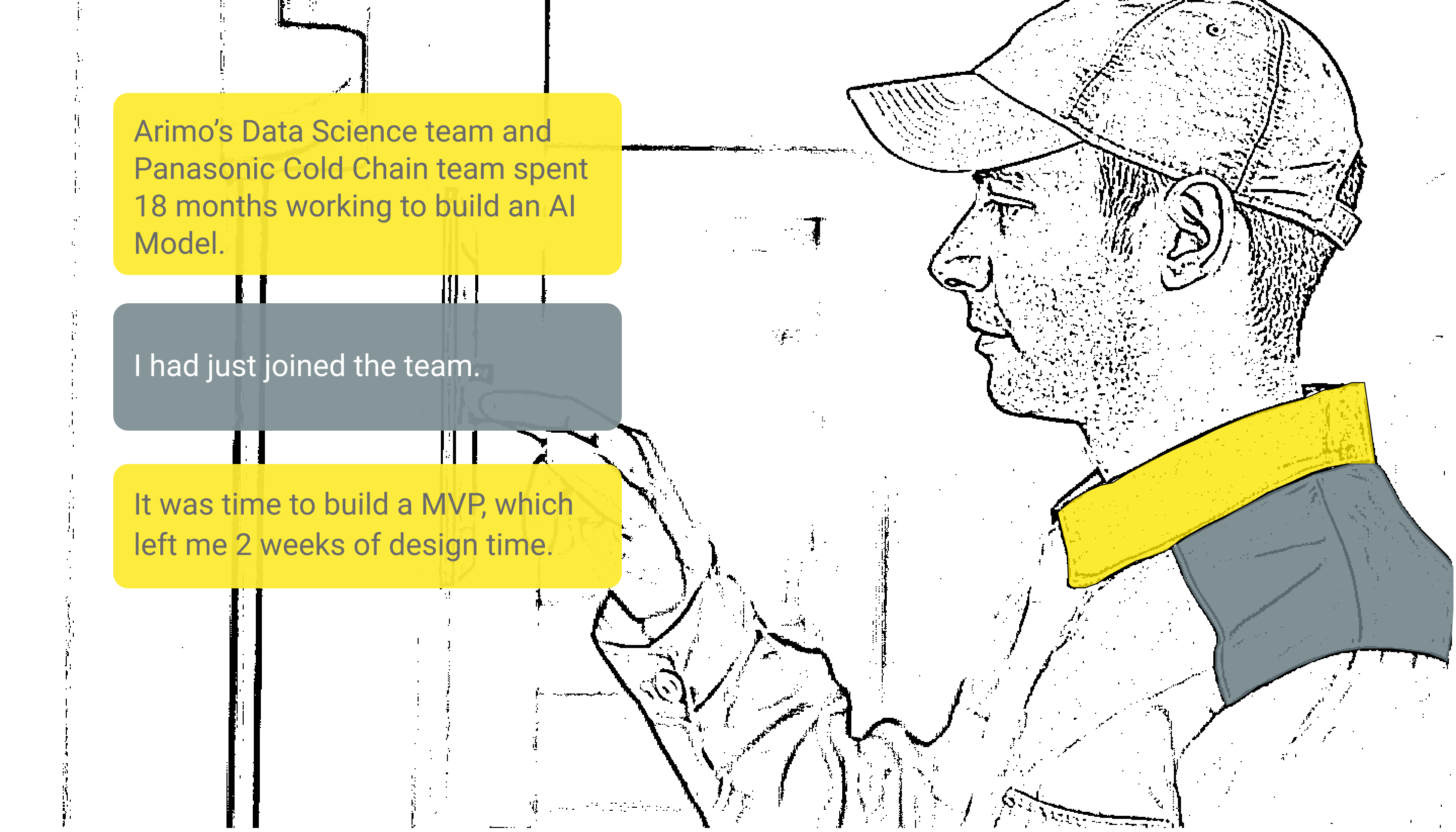

Implementation Support - MVP

Collboration With Engineering Team

Post MVP What We Learnt

Maintenance Engineers Diagnosed 10 Anomaly Cases Over 15 Days

Collaborated With Panasonic's User Research Team

User Research & Validation

I helped facilitate user research with 6 Maintenance Engineers to understand:

- User Demographics

- What are their current pain points?

- What was their experience using first version?

Research Download

Cannot analyze anomalies

The user is not clear about what contributes to their equipment risk score.

The user expects to zoom in and out of the graph.

The user wants to plot basic charts that they view by default.

Wants past diagnostic history

The app should have the ability to identify if the equipment has had similar issues in the past and should show relevant issues to the users if there was an anomaly and/or if a diagnosis took place.

Cannot collaborate with experts

There is not enough expertise in the organization, so they need the ability to share analysis with peers and experts.

Version 2 - Vision: Easy Analysis

Based on the research, we set our vision to improve the analysis experience for our users so that they could diagnose and complete more cases.

Version 2 Final Design - Easy Analysis

Design Impact

Summary